- Get link

- X

- Other Apps

In order to develop these models the failure rates and. Damage was imprinted on all teeth because the gear set had a hunting gear ratio.

Are Wind Turbines Designed To Fall Apart So That They Need To Be Replaced By Rosemary Barnes Ux Collective

Are Wind Turbines Designed To Fall Apart So That They Need To Be Replaced By Rosemary Barnes Ux Collective

Over the last nine years wind has grown by 55 and only 13 in 2019.

Wind turbine failure. The gearbox of a wind turbine is responsible for converting the relatively slow rotations of a turbines blades into the high speeds needed to generate electricity. According to the website a blade failure. A WIND farm has been switched off after a turbine malfunctioned and sent debris falling into the field below.

Every 2 GW of fossil generation is only with replacement by rebuilding the entire wind infrastructure plus a pumped storage facility of the size of snowy Mountains 20 again. A project was therefore started as project V-375 ConFail Investigation of converter failure in wind turbines. If it freezes up and has to be stopped for deicing THAT s a failure too.

Energy demand was met by wind energy with that percentage predicted to increase to 20 by 2030. According to the latest statistics from the database the majority of wind turbine gearbox failures 76 are caused by the bearings. Axial cracks that form on the bearings during high- and intermediate-speed stages are the leading cause for bearing failures and are the focus of a joint research effort by NREL and Argonne National Laboratory to identify the root causes and develop mitigation.

Challenge to wind turbines In 2019 73 of US. These hard-working components often do not reach their expected 20-year lifetime despite meeting industry standards because of a failure mode called axial or white-etch cracking in the rolling-element bearings inside the. The main problem is the use of wind for energy.

For example it is now possible to roughly predict failure occurrence rates and total cost of repair for four common wind drivetrain failures. It includes Power Poing presentations by Timken Gruel Kjaer Virbro and Delom Service Wind Division. The failure of roughly half of the wind turbines in Texas earlier this week isnt the biggest cause of a power shortage crisis that has left one-third of Texans without power in historic freezing.

Wind is growing very slowly and that will continue at that place. Nearly 120 wind turbines catch fire each year according to a research - ten times the number reported by the industry. If a windmill is operating as designed which means no wind no power then is has not failed.

Martin said the two main causes of wind turbine failures are fires in the gear box and blade failures. Photo from GEARTECH NRELPIX. If it catches on fire and some have THAT is a failure.

Improve the designed-in reliability and robustness of wind turbine components and subsystems as well as the. Wind turbine rotor blades are failing at a rate of around 3800 a year 054 of the 700000 or so blades that are in operation worldwide. It will not happen.

The researchers claim that out of 200. The top five wind turbine fails and mishaps. Wind turbine reliability data comprise the historical failures repairs and downtimes of a turbine and its subassemblies.

A thorough understanding of WT reliability is critical to the development of effective operation and maintenance OM strategies and. Use accelerated life testing and stress testing to determine the failure modes of the wind turbine components. Here reliability and failure prediction models can enable operators to apply preventive OM strategies rather than corrective actions.

These machines help power our world but they som. Investigations are underway as to the cause of the failure at Park Spring wind farm Grimethorpe at around 3pm today March 12. Reducing premature bearing failures in wind turbines will make wind energy more cost competitive and reliable.

Mechanical wear and tear including bearing failure is one of the most common reasons for turbines to be put out of action. Wind is a failure. Bearing and gearbox failures.

Polishing wear severe local Failure mode 3. Determine the root causes of each. Experience is improving estimates of failure times for critical components such as bearings said experts at the 3rd Annual Wind Optimization Maintenance Canada conference.

A blade from one of the sites trio of four-year-old turbines became detached and fell almost 100m to the ground. One windmill plus no wind zero power. Annual blade failures estimated at around 3800 Windpower Monthly Annual blade failures estimated at around 3800 WORLDWIDE.

And is one of the key factors that accounts for the fact that the economic life of wind turbines is 10-12 years which runs contrary to wild claims about them lasting for 25-plus years see our post here and this paper. Find out what happens when a wind turbine meets too much wind. Scuffing severe local Description.

Frequent failure of the power-electronic converters in offshore wind turbines is a problem with considerable impact on the turbine availability and therefore the revenue from production as well as on the maintenance cost. Fretting corrosion severe Failure mode 2. Turbine failure sees wind farm shut down.

Good News Wind Turbine Collapses Sierra Club

Vestas Blade Failure At Edp S Ohio Wind Farm Renews Renewable Energy News

Vestas Blade Failure At Edp S Ohio Wind Farm Renews Renewable Energy News

Wind Turbine Fire Due To Mechanical Failure Onyx Insight

Wind Turbine Fire Due To Mechanical Failure Onyx Insight

Fortune Favours The Bold Wind Turbines On Fire

Fortune Favours The Bold Wind Turbines On Fire

Fires Are Major Cause Of Wind Farm Failure According To New Research Imperial News Imperial College London

Fires Are Major Cause Of Wind Farm Failure According To New Research Imperial News Imperial College London

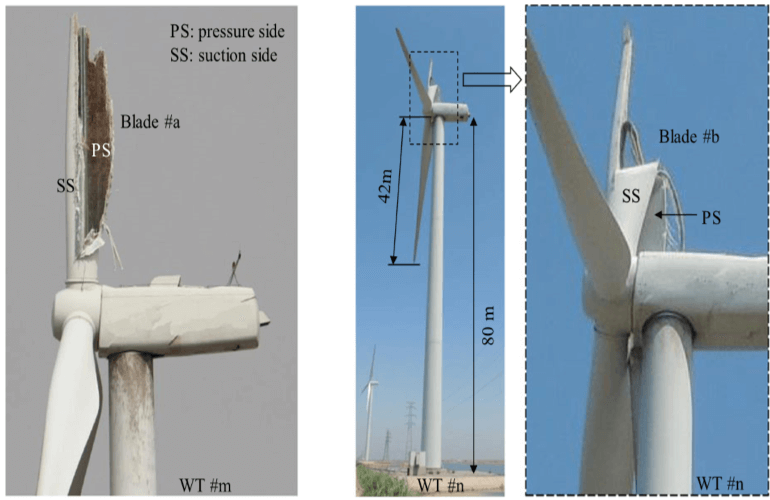

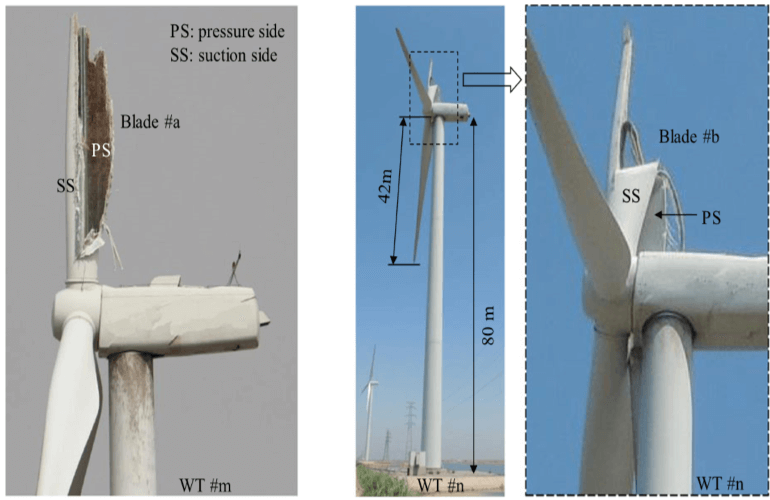

What Researchers Have Learned From Fractured Wind Turbine Blades

What Researchers Have Learned From Fractured Wind Turbine Blades

Wind Turbine Collapses Outside Hunter Cause Under Investigation Ag Energy Enidnews Com

Wind Turbine Collapses Outside Hunter Cause Under Investigation Ag Energy Enidnews Com

Are Four Wind Turbine Failures In Five Weeks Too Many For Nextera Energy 2017 07 13 Enr

Are Four Wind Turbine Failures In Five Weeks Too Many For Nextera Energy 2017 07 13 Enr

Wind Turbine Blade Throw Stop These Things

Wind Turbine Blade Throw Stop These Things

Huge Vestas Wind Turbine Collapses In Northern Sweden In Rare Accident

Huge Vestas Wind Turbine Collapses In Northern Sweden In Rare Accident

Finally Ge Engineer Shares Reasons For Multiple Turbine Failures

Finally Ge Engineer Shares Reasons For Multiple Turbine Failures

Too Much Wind 10 Wind Turbine Fails Youtube

Too Much Wind 10 Wind Turbine Fails Youtube

Exelon Mechanical Failure Led To Turbine Collapse Wind Energy News

Exelon Mechanical Failure Led To Turbine Collapse Wind Energy News

Comments

Post a Comment